Knock on wood, I’ve not yet had to deal with the nastiness that comes from galvanic corrosion aboard a boat… But then I really haven’t paid much attention to the issue aboard my previous vessels. Sure I changed the prop-shaft zinc when I hauled Uno Mas out for bottom painting every year, but since I never really left her plugged in to shore power for longer than a week or so, I never really gave my anodes much thought. Now that my home is my boat (and for the time being I’m plugged in to shore power), I am making a habit out of carefully monitoring my cathodic protection. I hope to make a monthly checkup of all my anodes and report my findings here.

Rua Hatu’s grounding system makes contact with the big blue in four different underwater locations; at the prop shaft, at all of the metallic through-hulls, at a tear-drop fitting just above the prop aperture on the port side and finally at the large steel grounding plate mounted in the starboard side of the keel (for grounding the SSB).

When we purchase Rua Hatu in May of this year, I noted the heavily corroded tear-drop zinc just above the prop aperture. The red bottom paint on the zinc itself indicated that it had been there prior to the previous owner hauling and painting the boat in 2018. The yard where we had her hauled didn’t have any such zincs on hand, so I opted to replace the prop shaft collar and call it good for the time being.

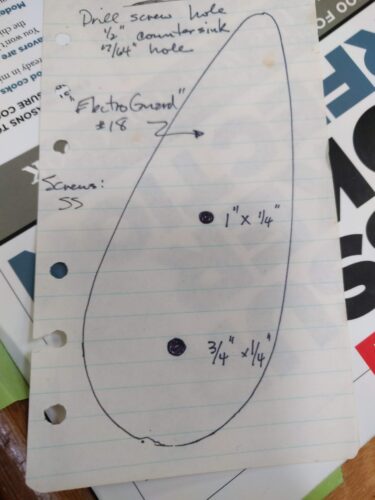

Replacing the teardrop zinc has been on my list of to-dos ever since, but first I needed a suitable replacement. The original and previous owner/builder kept meticulous records of all this vessels systems and thankfully made a nice sketch of the teardrop zinc including a brand name! Turns out ElectroGuard Galvanic Corrosion Protection is still in operation out of Southern California, and quickly shipped me 5x of these unique little buggers and a handful of limited-clearance prop shaft zincs as well. With these on-hand, I feel like we’ll be set for the next several years.

Fully equipped, I donned my wetsuit and took the plunge here in the marina on Christmas day. I discovered (to my pleasant surprise) that the teardrop had not deteriorated significantly from what I had found in May. The prop shaft zinc also appeared to be in good shape, and despite some hard growth on the SSB grounding plate, no significant corrosion was visible. The two stainless bolts holding the teardrop in place gave way with only a little hesitation, and I soon had a brand new teardrop zinc installed. Here’s hoping they do their job diligently in the coming months!